Home/Product

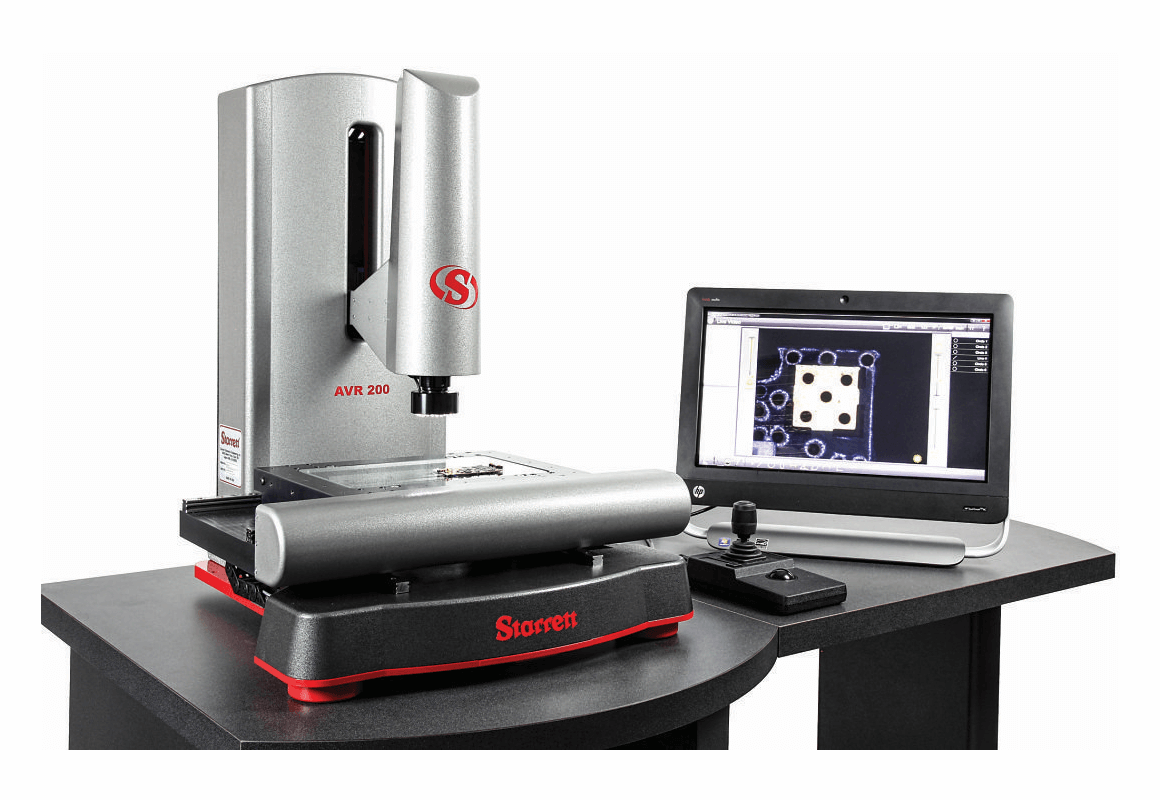

AVR200/AVR300 CNC Vision System

ID:AVR200/AVR300

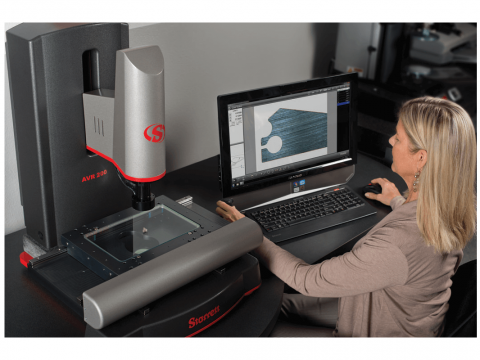

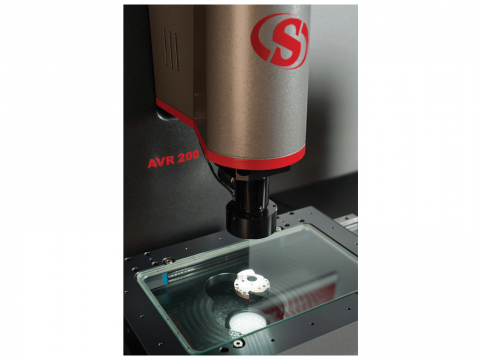

The AVR CNC Automatic Vision Metrology Systems are ideal for repetitive measurements and automatic comparison to CAD files. Systems are available with interchangeable telecentric or dedicated zoom lenses for micron-level resolution and accurate field-of-view (FOV) measurements. With a maximum FOV of 0.93" (24mm), the AVR series is capable of measuring parts with a length up to 8" (200mm) or 12" (300mm) for the AVR 200 and 300, respectively. A large 2.36" (60mm) FOV-dedicated 0.14X lens is now available. The operator interface is the MetLogix M3 software that displays a live video image of the part plus geometry tools and digital readings. The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch-screen monitor. M3 software capabilities also include 3-axis measurements and 2D geometric constructs (points, lines, angles, rectangles, slots, blobs). Systems are also touch probe compatible.

-

- Z travel: 8" (200 mm)

- Full CNC X-Y-Z positioning or motorized manual positioning using a pendant with joystick and trackball

- Metlogix M3 metrology software

- Video edge detection (VED)

- Field-of-view (FOV) measurements integrated with stage motion

- Renishaw scales for 4 µin (0.1 µm) of X,Y and Z axis (available on select models)

- Color digital video camera

- Collimated LED sub-stage illumination

- Ring light LED surface illumination (dome light on FOV 0.14)

- Granite base

-

Starrett AVR and MVR Vision Systems

-