Home/Product

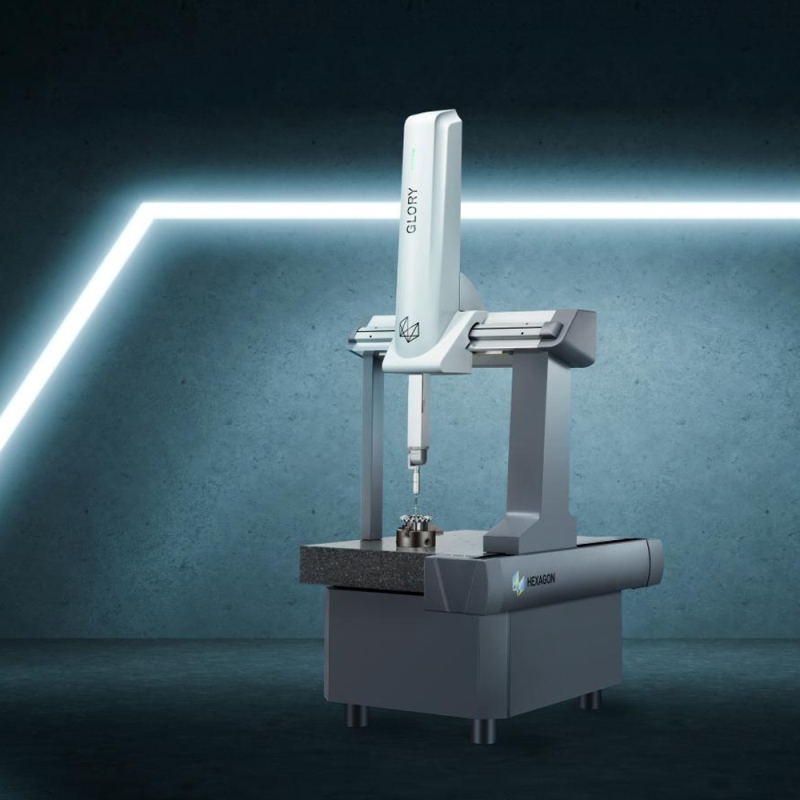

Glory Series Bridge CMMs

ID:Glory

The GLORY bridge coordinate measuring machine (CMM) is a new generation of universal measuring machine built upon Hexagon’s innovative and advanced technologies, user research and close customer collaboration. Its flexible design platform ensures that it can be configured to meet a wide variety of user requirements. The GLORY CMM is designed to meet the needs of modern manufacturing and is dedicated to providing users with a full range of intelligent manufacturing solutions.

-

GLORY bridge CMMs provide consistent and reliable measurement results, from inspecting manufacturing materials to measuring during machining and assembly. Its unique design and core technology advantages help users shorten and optimise cycle times and make better use of inspection equipment to maximise productivity. The CMM supports the fast changeover of inspection methods to fit the requirements of different parts and features and meet a broader range of measurement applications.

Carbide aluminium mechanical frame

The frame is surface hardened for extra rigidity. The lightness of aluminium, its good thermal conductivity and its adaptability to temperature changes provide the optimum material for a universal measuring system.

One-piece granite stage

The solid and stable granite table reduces vibration and supports smooth bridge movement.

Pneumatic balancing technology

The flexible suspension system avoids interference between axial movement and the drive train and ensures high positioning accuracy, smooth running and saves energy.

HEIDENHAIN scales

High-resolution encoder system, excellent measurement stability, repeatability and accuracy. Unaffected by interference, wear-resistant, stable and reliable.

Reinforced timing belts

Reinforced timing belts with built-in steel wire combine flexible engagement and rigid axial drive characteristics to ensure precise positioning and eliminate jitter during high-speed scanning.

Integral dovetail guides

Precision-machined integral dovetail guideways and pre-loaded air bearings in all axes ensure stable movement, accuracy, repeatability and long-term stability.

Messaging light

The multi-coloured LED signal light integrated into the top of the Z-axis allows users to monitor the CMM’s status in real-time, even from a distance, optimising time and resource management.

TRICISION bridge

An optimal structural rigidity provides higher accuracy, long-term stability and improved dynamic performance. The triangular crossbeam is structurally robust and less prone to deformation under stress, allowing for faster operation, a smaller footprint and better thermal stability.

Measuring volumeType Measuring volume X (Width) Y (Depth) Z (Height) 04.05.04 400 mm 500 mm 400 mm 05.06.05 500 mm 600 mm 500 mm 06.08.06 600 mm 800 mm 600 mm 06.10.06 600 mm 1000 mm 600 mm 08.10.06 800 mm 1000 mm 600 mm 08.15.06 800 mm 1500 mm 600 mm 10.12.08 1000 mm 1200 mm 800 mm 10.15.08 1000 mm 1500 mm 800 mm 10.21.08 1000 mm 2100 mm 800 mm 12.15.10 1200 mm 1500 mm 1000 mm 12.22.10 1200 mm 2200 mm 1000 mm 12.30.10 1200 mm 3000 mm 1000 mm 15.22.10 1500 mm 2200 mm 1000 mm 15.30.10 1500 mm 3000 mm 1000 mm 15.22.12 1500 mm 2200 mm 1200 mm 15.30.12 1500 mm 3000 mm 1200 mm