Home/Product

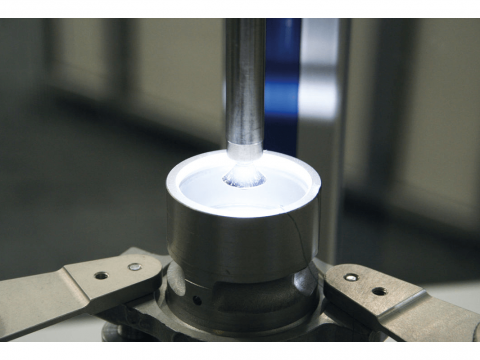

Optical bore inspection

ID:B5, B20, B100

Visionline B sensors are especially suitable for bore surfaces. They impress with their 360° all-round vision optics. In this automatic process, a CMOS sensor completely scans the inner surface of the bore and delivers high-resolution and high-contrast images. This allows for the detection of surface defects such as blowholes, porosity and scratches even during production. With Evovis Vision software, your employees evaluate the images easily and intuitively.

-

The optical sensors enable precise inspection of bore surfaces and deliver high-resolution and distortion-free

images of the surface in order to reliably detect defects within the required cycle time.- Visionline B5 for bores from 5 mm

- Visionline B20 for bores from 14 mm

- Visionline B100 for bores from 68 mm

System features

– Latest CMOS image sensor technology and a 360° lens for reliable and automated inspection

– Objective test results without influence of the operator

– Detection of common surface defects such as cavities, pores, scratches, etc.

– Process-reliable differentiation of defects and residual dirt from drying

– Image pickup whilst in motion and within the required cycle time

– Large diameter ranges, therefore no conversion necessary when changing workpieces

– Head-on collision protection to avoid damage in case of workpiece misalignment

Modular system concept

– Offline with manual loading

– Inline with automated workpiece handling

– Flexible robot system

– Multiple sensors as well as combination with other sensors (e. g. F200S) in one system possible

Application examples

– Valve control plate

– Brake master cylinder

– Pump housing

– Con rod

– Cylinder liner, and many more