Home/Product

QC20 Ballbar System

ID:QC20

Renishaw's QC20 ballbar offers you the perfect solution. It's the quickest, easiest and most effective way to monitor machine tool condition.

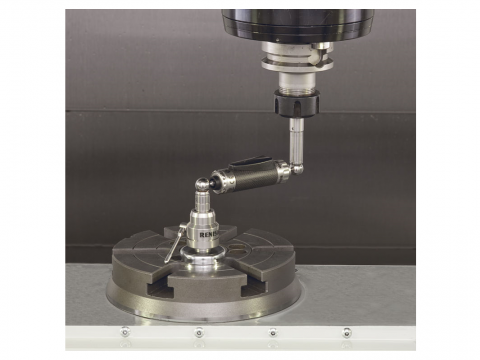

The heart of the system is the ballbar itself, a very high accuracy, telescoping linear sensor with precision balls at each end. In use the balls are kinematically located between precision magnetic cups, one attached to the machine table and the other to the machine spindle or spindle housing.

-

The QC20 system draws on Renishaw's many years of experience with ballbar testing and offers significant performance and operational benefits:

- Bluetooth wireless technology ensures no wire handling issues, closed door operation and reduced possibility for system damage.

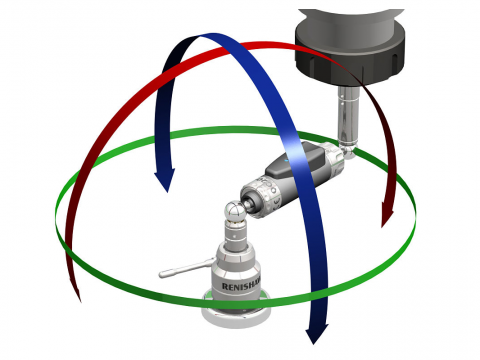

- New hardware and software which allows a 'partial arc' (220°) test. This gives you greater test flexibility including:

- Improved Z axis testing (no custom fixturing required).

- Tests where axis travel is limited (typically Z axis on machining centres and X axis on lathes).

- Ability to test 3 planes from a single set up, using 'partial arc' tests for 2 of the tests and present a 'volumetric analysis'.

- Faster data reading for enhanced analysis on small test circle and high feed rates.

- Enhanced software includes many new features for extended testing and greater ease of use.

-

QC20 wireless ballbar test

-